RECENT POSTS

Don't Miss

Inclusion of women in construction industry

Growing up as a Nigerian from one of the least developed communities, I have identified that our continent Africa and Nigeria in particular has...

How to Apply Wind Load on Roofs of Buildings

Wind load is one of the significant actions on roofs. While other loads such as the self-weight of materials, imposed loads, service loads, and...

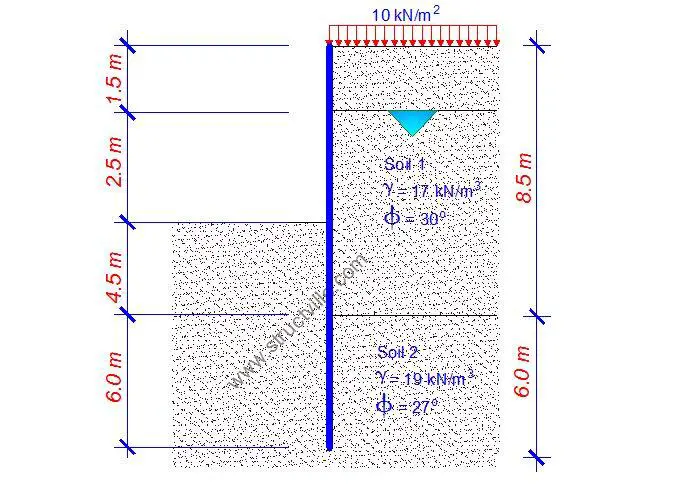

Worked Example | Analysis and Design of Steel Sheet Pile Wall (EN 1997-1)

This article contains a solved example of the analysis and design of steel sheet pile walls in accordance with BS EN1997-1:2004 - Code of...

Setting Out of Buildings: Approaches and Best Practices

In the construction of buildings, setting out is the critical first step on the path to successful construction. This process involves translating architectural plans...

Application of Genetic Algorithm to the Design of Pile Foundations

Machine learning and deep learning techniques have been widely applied in the design of civil engineering structures in recent years. This is mainly due...

Application of Wind Load to Shear Walls – A Manual Approach

The higher a building goes, the higher the effects of lateral forces such as the wind on the structure become. Shear walls are...

Digital Fabrication with Concrete and Sustainable Designs

Over the past few years, the subject of digital fabrication with concrete has advanced significantly, with numerous alternative techniques having been created and numerous...

Strengthening Flat Slabs against Punching Shear

Punching shear is one of the most critical failure modes in flat slabs, characterized by its catastrophic and brittle nature. In existing buildings, there...

Recent Comments